In order to achieve high quality precooked corn flours, the corn is cooked after degermination and prior to refining. In this way, large particles are used to obtain the appropriate cooking and at the same time a high quality film.

This treatment inactivates or destroys possible anti-nutritional factors and improves the digestibility and availability of the different biochemical constituents.

It is a thermal or hydrothermal treatment combined with a mechanical treatment. The main focus is on disorganizing the crystalline structure of starch to reach its gelatinized state.

These procedures alter starches that possess hydroxyl groups, which are not very soluble in water. The alteration of these groups by hydrothermal processes increases the water retention power and facilitates the swelling and gelatinization of the starch grains.

Pregelatinized starches, cooked and crushed on rollers and then dried, swell directly in cold water, which they retain well.

The temperature at which these phenomena occur is called the gelatinization temperature and is associated with the breaking of the secondary hydrogen bonds that hold the polymer chains together. The gelatinization temperature for barley is in the range of 59-64ºC, for wheat 65-67ºC and for sorghum between 67 and 77ºC.

Understanding the pregelatinization process is important to understand the practical significance of facilitated starch digestion.

It is important to note that gelatinization of starch by cooking makes it more digestible than by amylolytic enzymes.

Description of the flaking process:

Flaking is a thermomechanical “cook-laminate” process to which cereals are subjected.

Cooking is done with low pressure steam while flaking basically consists of crushing the grain into thin sheets. In this way, the starch in the grains is transformed into less complex substances, such as dextrins and sugars (chemical effect of heat-pressure) and the starch grains lose their crystalline structure, giving rise to the phenomenon of gelatinization (physical effect). The product obtained after drying is called “cereal flakes”, the advantages of which are:

- Eliminate bacteria and eventually the development of toxins that may appear in prolonged storage conditions.

- Inactivate anti-nutritional factors.

- Modify the physical appearance of foods.

- Increase voluminosity.

- Increase the bulkiness.

- Increase the volume of the food.

- Intensify the degree of particle imbibition.

- Increase starch digestibility by its transformation into dextrins.

- Increase starch digestibility.

The process is articulated in three phases:

Phase 1: Hydrothermal treatment.

It consists of distributing uniformly, in the cooking chamber, water vapor at low pressure (one atmosphere). This is permanently mixed with the corn so that the product receives the pressurized heat at the same time and at the same temperature. To avoid overheating or, alternatively, a deficient degree of cooking, temperature sensors are placed in the system.

Phase 2: Mechanical treatment.

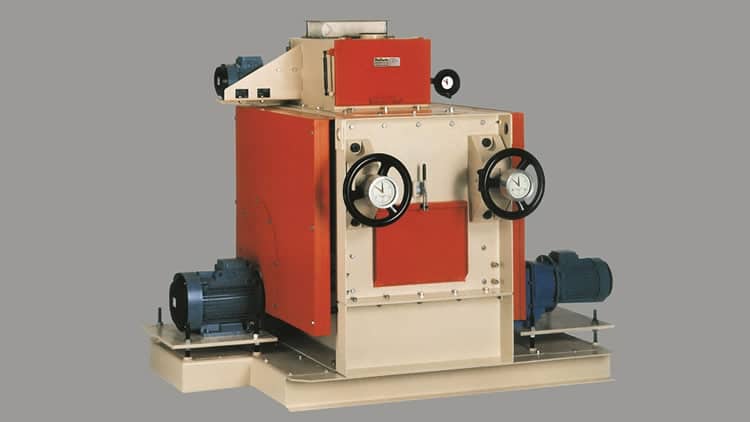

It is performed by a rolling mill with two opposed cylinders. In this machine it is very important the uniform feeding along the whole rolling surface. It is possible to make a fine scoring of the crushing surface which facilitates the flake detachment and its thermal conductivity.

Phase 3: Drying and cooling treatment.

Moisture and temperature are removed in a desiccator where the flaked product passes through streams of hot and cold air. This results in a product with a humidity of 13% and a temperature close to room temperature

Technical information