Considered today as one of the most efficient means of transporting products due to its safety, hygiene, precision and reliability, pneumatic conveying is the solution to a multitude of product movement problems.

Adaptable to any need in terms of capacity and length, this technology greatly simplifies the transfer of products between production sectors. With extensive experience in the application of this system, Prillwitz has specialized in the application of pneumatic conveyors for a wide variety of products, employing specific techniques for each of these.

What are the possible machines to generate air for pneumatic conveying?

A regenerative turbine, a rotary piston blower or a high pressure centrifugal fan can be used to generate the required air. In the case of using a compressor, it is possible to insert an air-to-air cooler for pneumatic conveying in order not to deteriorate the characteristics of the product.

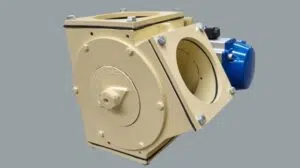

Three-lobe rotary piston blower ASR3 – type Roots

We have been supplying compressors for more than 60 years, when we started representing Aerzen of Germany. The 3-lobe rotor blowers of the ASR3

Regenerative turbine Blower

Regenerative turbine Blowers or side channel blowers are reliable and efficient equipment used for different applications, mainly for pneumatic transport, with flow rates up

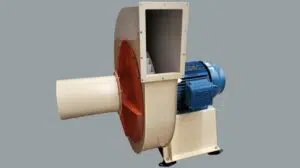

HT high pressure centrifugal fan

HT high pressure centrifugal fans have been designed trying to achieve the highest possible performance in applications where high air flow rates are required

What are the necessary accessories to create a pneumatic transport system?

Among our accessories for pneumatic conveying, the HSP rotary valves and HSD extraction sluices that ensure the loading and unloading of the product into the pipeline with absolute tightness stand out. VTN and VTNG valves allow diverting the pneumatic conveying lines to different discharge points.

HSD rotary airlock valve for vertical passage or extraction

The HSD vertical discharge valve is a dust control system used as a seal in the discharge of pneumatic conveying systems, under air filters

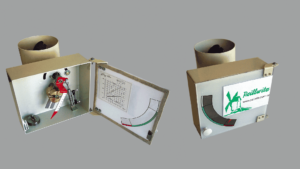

HSP rotary or horizontal sluice valve

Specially designed for product intake in horizontal flow in pneumatic conveying lines, the HSP rotary valve allows an ideal mixing of the product with

HSG rotary airlock valve

Like any rotary airlock valve, its function is to allow the flow of the product, without letting the air escape. This model is designed

VTN pneumatic conveying diverter

The VTN Diverter Valve is used for the pneumatic conveying of products without the need to empty the pipeline. Thanks to their innovative circular

VTNGa Pneumatic conveying rotary diverter

New concept in equipment for pneumatic conveyor track changing The design of the VTNGa diverter valve, allows to divert products by turning a rotor,

Self-adjusting valve for pneumatic suction conveying VAR

Ideal for lowering energy consumption in the pneumatic parallel suction conveying system This valve is employed as a substitute of non-self-adjusting valves that are

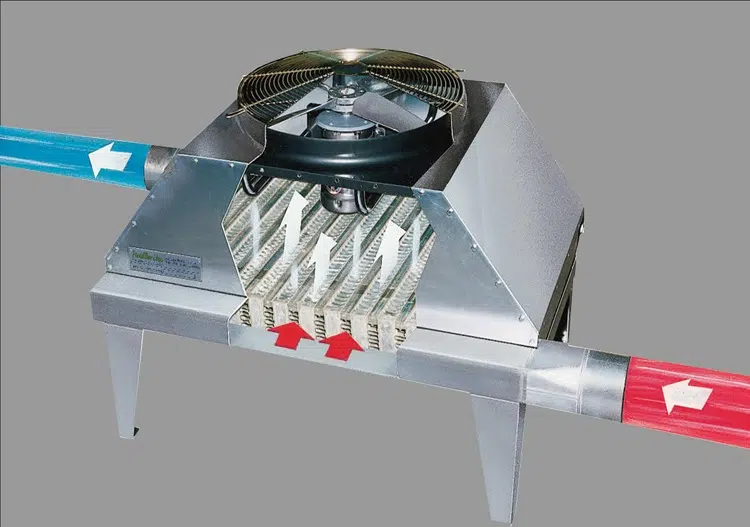

Air-Air Exchanger for pneumatic transport

In the case of using a compressor as a transport air generator, a significant temperature rise occurs. This is why, for some sensitive products, it is advisable to insert an air-to-air cooler. Examples of this need could be for the transportation of sugar or some plastics.

Frequently asked questions:

A pneumatic conveying system is a way of moving a dry powder or granular product in bulk by mixing it with a gas, usually air, which carries it through a pipe.

In dilute phase pneumatic conveying, the particles are conveyed through ducts at high speed with a large amount of air at low pressure. It can be either by impulsion or suction.

Pneumatic vacuum or suction conveying is an efficient way to move powdered or granular solids, which are fluidised by the air generated by the vacuum pump. They then flow freely through the pipes to their destination.

It is used throughout industry for the movement of powders and granules. It has the following main advantages over mechanical conveying systems such as screw conveyors or bucket elevators

- It allows conveying paths of highly variable geometry, without the limitations of the aforementioned conveyors, which generally only allow horizontal and vertical conveying.

- They leave the installation much cleaner of the remains of the conveyed product, when completed.

- They take up less space and are cleaner for the surrounding environment, as they are closed systems.

The advantages of dilute phase pneumatic conveying are the flexibility of transfer in limited or small spaces, the suppression of dust in the environment and easy maintenance.

The advantages of vacuum conveying include dust suppression and leak containment. It can also be applied in explosive atmospheres, with safe and graceful receivers, adapting the system to customised demands.

Thanks to the vast experience in the implementation of pneumatic and mechanical conveying systems, Prillwitz has the necessary know-how to adapt the various machines to the particular product to be conveyed, through the application of specific techniques.

Raw materials that we have moved with pneumatic conveying:

- Wheat

- Maize

- Oats

- Coffee

- Cocoa

- Rye

- Beat

- Rice

- Girassol

- Chickpeas

- Soybeans

- Peanuts

- Peanuts

- Spices

- Balanced feed

- Pellets or feeds

- Crystalline sugar

- Impalpable sugar

- Cocoa

- Coffee

- Coriander

- Curcuma

- Gelatin

- Bone meal

- Fish flour

- Milk powder

- Dried beans

- Bread crumbs

- Batter

- Aluminum powder

- Atrazine

- Bentonite

- Borax powder

- Lime

- Caolin

- Activated carbon

- Calcium carbonate

- Cement

- Shell

- Quartz

- Titanium Dioxide

- Dolomite

- Fertilizers

- Monoammonium Phosphate

- Diammonium Phosphate

- Tricalcium Phosphate

- Mica

- Refractory Materials

- Sodium naphthalenesulfonate

- Pigments

- Soaps

- Salt

- Precipitated silica

- Caustic soda

- Magnesium sulfate

- Zinc sulfate

- Tanine

- Diatomaceous Earth

- Dyes

- Gypsum

- Lithium

- Afrecho and afrechillo

- Wheat semolina and semolina

- Semolina

- Rebasillo

- Zootechnical flour

- Maize semolina

- Semolina

- Polenta

- Wheat flour, corn flour, soy flour, etc.

- Germ

- Starch

- Hull

- Polycarbonate

- Vinyl polyvinyl chloride or PVC

- Polystyrene or PET

- Polyethylene

- Polypropylene

- Expanded polystyrene (Styrofoam)

- Sawdust

- Wood

- Cork

- Soap poder

- Pigments