PA breaker is used to break up flour flakes that would otherwise be mistaken for husks by the sifters and consequently discarded. On the other hand, unlike the detacheur, it also produces a small grind and thus contributes to the work of the Rolling mill.

It is also used, in the food industry, to remove any insects that the product may have.

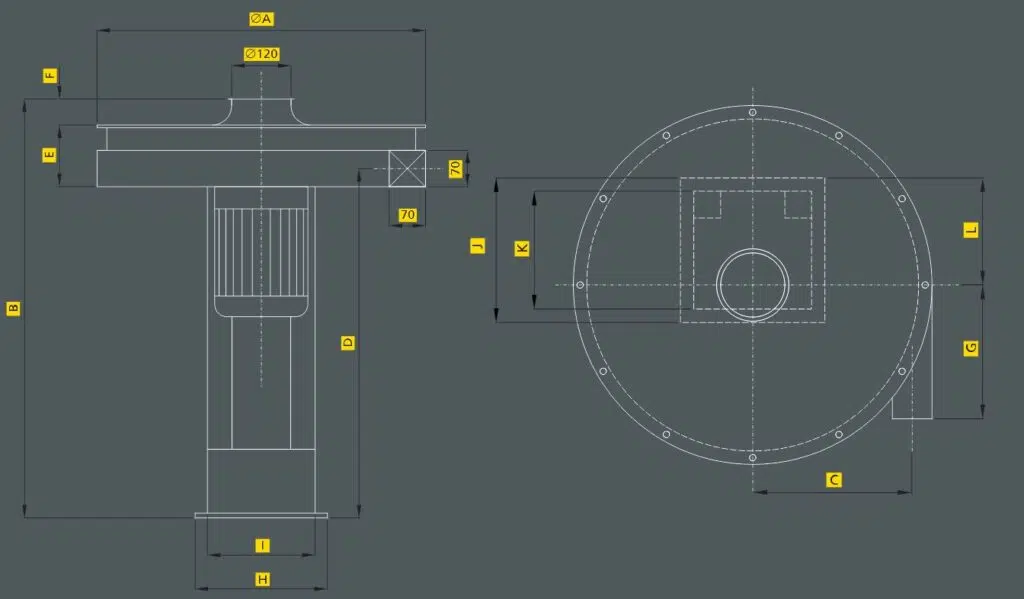

The Disintegrator can be supplied in two versions: the PA model and the Impactor.

In our PA product refining and disintegrating machine, a rotor hits the product hard and impacts it perimetrically on the disintegrator body, after which it falls into the collecting channel.

In the Impactor, this work is more intense since its diameter is larger.

As an alternative, the Impactor B also has fixed pins, so that the particles or semolines impact between the pins, producing a great extraction of flours.

Thanks to their innovative design, the disintegrators offer an unbeatable capacity-to-consumption ratio.