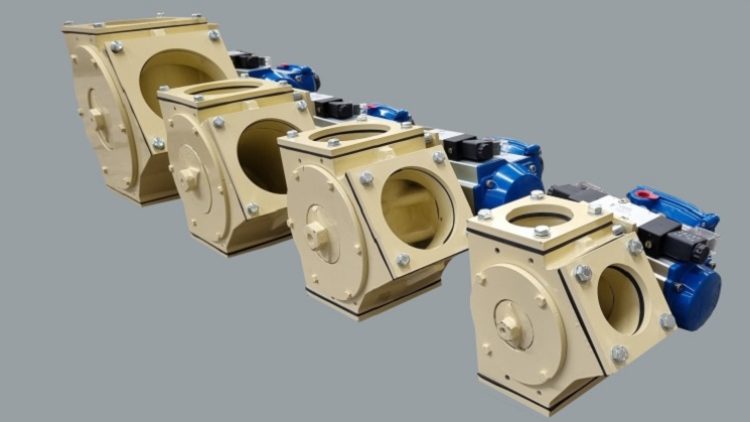

New concept in equipment for pneumatic conveyor track changing

The design of the VTNGa diverter valve, allows to divert products by turning a rotor, which connects one lane to the other, ensuring a perfect and durable seal, even at high pressures.

Of robust conception, our VTNGa rotary valves stand out from others that have mechanical elements that wear out easily.

VTNGa rotary valves can be supplied with manual control or with rotary actuator and solenoid valve. It is also possible to incorporate position detecting microswitches.

Normally, they are manufactured with cast aluminum body and rotor, steel shafts and bronze bushings. Depending on the type of product to be conveyed, it is possible to manufacture them in different materials.