The Vibrating Fluidizer for silos and hoppers prevents the formation of vaults or bells by keeping the dry bulk materials being discharged constantly in motion. It prevents clogging, void formation and compaction by forcing the product to flow uniformly.

It is commonly used in the discharge of storage silos, bag filters, hoppers and weigh hopper scales.

Some of the reasons why our silo vibrator works where others have failed are:

- Unlike vibrators made of textile material, the silicone disc does not absorb moisture that can cause mold and mildew to develop.

- The silos or hoppers can be washed and cleaned without having to wait for the textiles to dry.

Know why our silo fluidizers are your best choice:

They have a sanitary design.

- Unlike vibrators made of textile material, the silicone disc does not absorb moisture that can cause mold and mildew to develop.

- The silos or hoppers can be washed and cleaned without having to wait for the textiles to dry.

They have a solid silicone disc.

- The food-grade disc resists hardening, cracking and tearing.

- It withstands temperatures up to 170°C.

- Available in green or white color.

Perfect for all types of silos.

- Discs close against the silo wall and prevent the air ducts from clogging with product.

Perfect for all types of silos.

- Fit both conical and square hoppers.

- They do not cause damage to the silo like external vibrators.

- Easy to install.

- Economical.

Elements that make up the fluidizing system.

1 – Fluidizers in quantity N = 1 to 12

2 – Solenoid valve

3 – Pressure regulator

4 – Straight connector

5 – T-type connector

6 – 90° connector

7 – Flexible tube

8 – Pulse programmer for solenoid valve

9 – Air tank

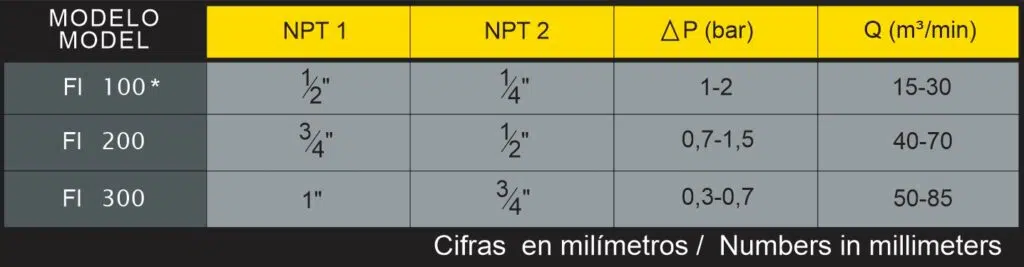

Technical information:

* Standard model

**It is recommended to install an air pulse timer and a pressure regulator to reduce compressed air consumption.

More information in the following links