As the name suggests, this is a flat sifter. The sieve is in a perfectly horizontal position within a frame that supports it and the particles to be classified lie on it.

This is the most accurate form of sifting, and that is why laboratory sifters use the same principle.

In contrast to laboratory sifters, Plansifters have sieve cleaning elements called tapotines. They move in such a way that they keep the perforations of the sieve surface free of particles that get stuck in the perforations of the sieve surface. In general, wire or nylon fabrics are used as sieves.

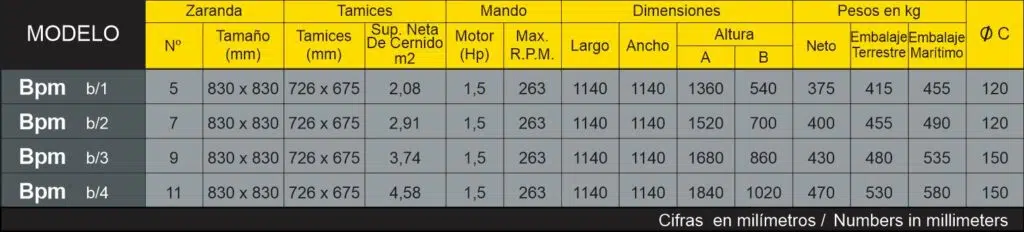

There are different types of screens that are best suited to each type of material or sieve perforation. Of these, the most common is the following one made of cotton.

Other types of tapotines:

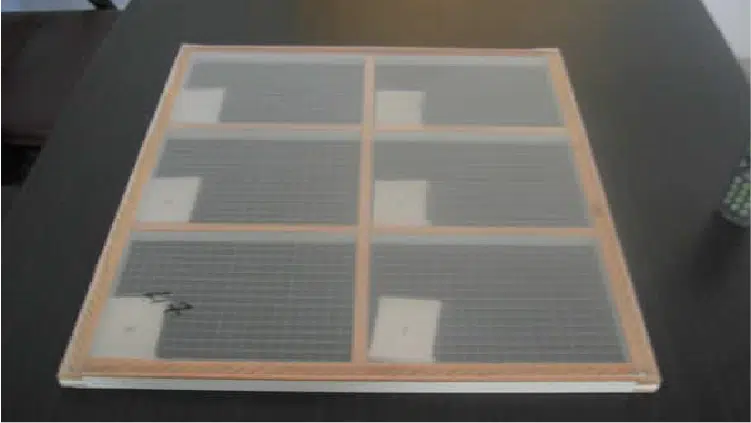

To facilitate the flow of the screened product into the outer channels, “Extractors” like the one in the picture are fitted.

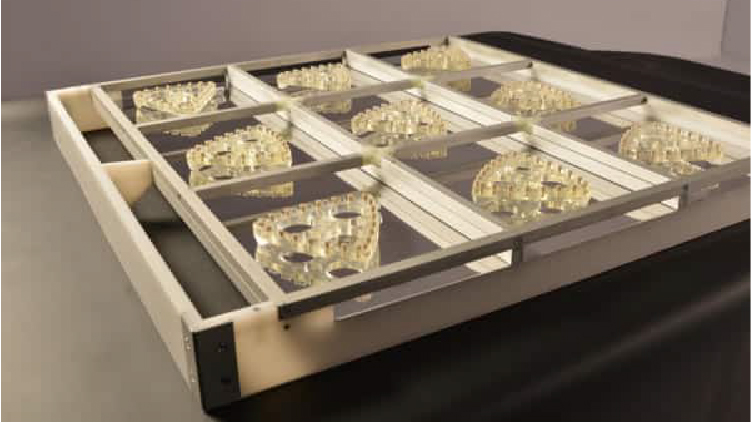

Sieves:

These are the boxes with the sieve on one side, and on the other side, they collect the different sorted products and guide them to the corresponding outlet. You can see the different alternatives at Plansifter Alternatives and Plansifter Lids PCA.

Loom: This is the frame that contains the sieve itself. In general, the sieve is glued to it. In the case of metal sieves, it is nailed to it with clips. This frame is interchangeable.

They are placed one on top of the other, so that the product to be sieved passes through them consecutively, falling from one to the other as the product advances. According to the number and type of classifications, the “Plansifter internal diagrams” are drawn up, which indicate the flow that the product will have over the different sieves.

They are currently manufactured in the following alternatives:

- General construction in wood lined with plastic laminate to reduce wear and tear. They can also be made with wooden or aluminium looms.

- General construction in synthetic material. In this case, the looms are always made of aluminium.

Construction materials: The original sieves were 100% wood.

Bottomless sieve shaker made of food-grade synthetic material with telerin or aluminium frame.

Plansifter types: We can classify them into 2 types, depending on whether the external product discharge channels are inside the screen construction or not.

High-capacity PC plansichter:

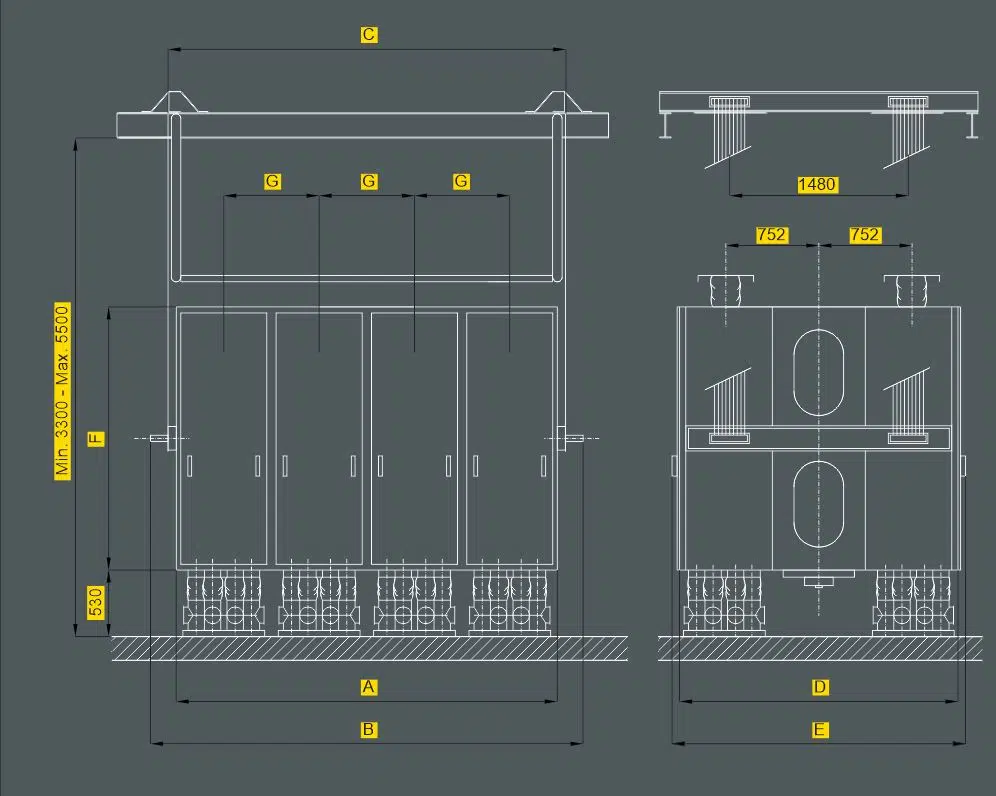

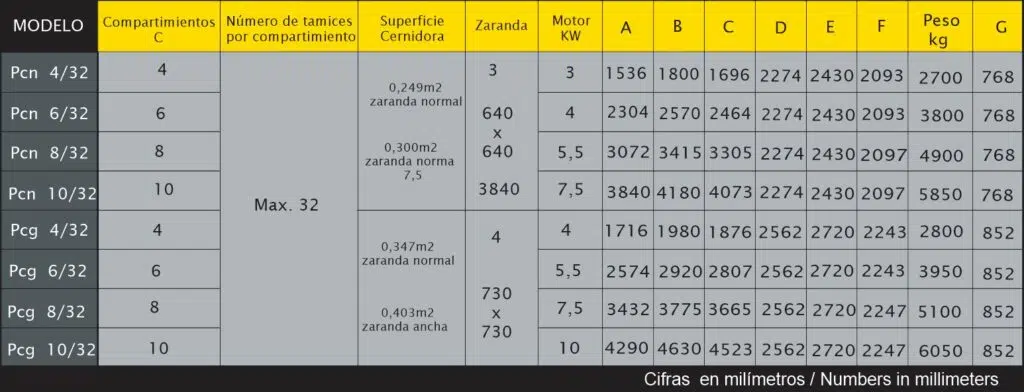

The outer channel is made of metal and the screens are fitted inside it. Each one has up to 10 sections or piles of screens. They are made up of three structures: two sieve-screener bodies and a control body.

Technical information

More information in the following links

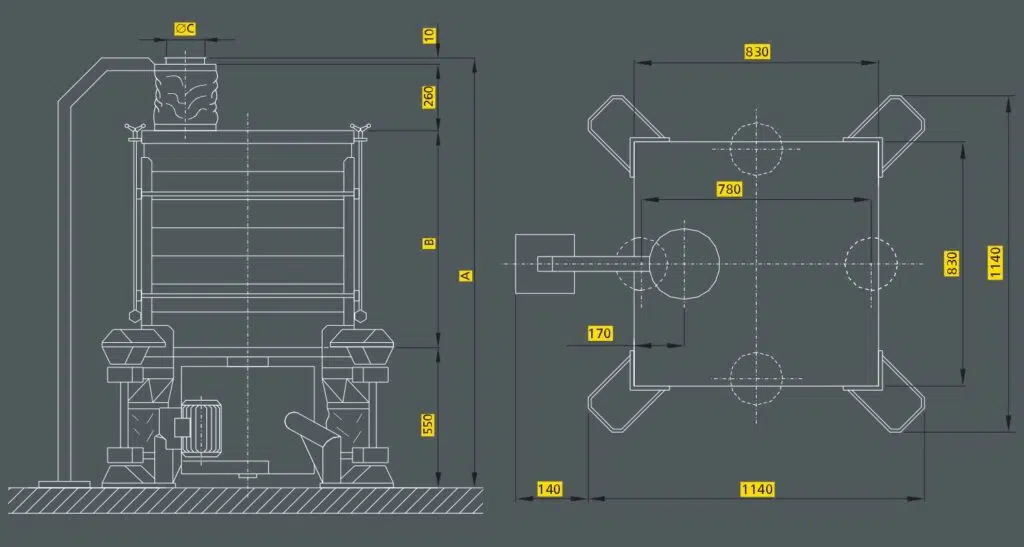

Monocanal BPM plansifter:

It has the outer channels incorporated in the sieve. We only manufacture it in the 1-section version.

The machine is supplied in the BPM(a) version, for suspension mounting with vertical rods, and the BPM(b), which is constructed with mounting feet with ROSTA® anti-vibration elements, which, unlike the old machines with rubber bushings, ensure perfect suspension with little maintenance.