Manufacturing of industrial storage silos: Steel, aluminum or stainless steel silos.

The stockpiling of products can be done in bags or in hoppers. But when it is necessary to stockpile raw materials in large quantities, we recommend the use of silos because they have the following advantages: they take up less space, facilitate cleaning and require fewer personnel. When combined with automated extraction systems and product feeding to the production line, the need for personnel is further reduced, also reducing the likelihood of human error.

We have the solution to your dry product storage problem. You can choose between a flexible trevira silo for indoor use; a metal silo for indoor use; or, if you need to store floury products outdoors, the metal silo for outdoor use will be the most advisable. The latter can be built in steel with different finishes, and even in stainless steel.

In Prillwitz we offer customized solutions for product storage and feeding to the production line. We have different unloading systems, conveying and sifting for dry products, depending on the product to be processed. We can also provide you with dosers, granulated product mills and state-of-the-art scales that guarantee rigorous production control.

Find here the silo that best suits your storage needs:

Outdoor storage silos

Conceived for location in outdoor spaces, our silos are manufactured under a meticulous production process to achieve 100% airtightness. They can be built in

Disassembled silos

The disassemblable silos are characterized by being widely versatile in terms of capacity and geometry (square and circular). They are normally used for indoors,

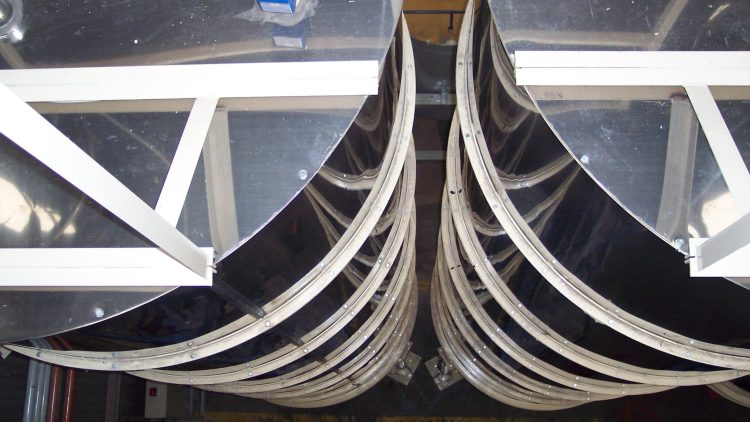

Flexible Silos

The flexible Trevira® fabric silos have been specially designed to simplify storage and unloading operations of dry bulk products. Our fabric silos have the advantage of being easily disassembled and of square section

For the installation of bulk storage systems, we have the necessary machinery to complete the silo installation. Feeding and discharge systems, mechanical and pneumatic conveyors, silo vibrators and fluidizers, dust collectors, cyclones, level indicators and detectors, sifters, mills, rotary valves, etc. are required.

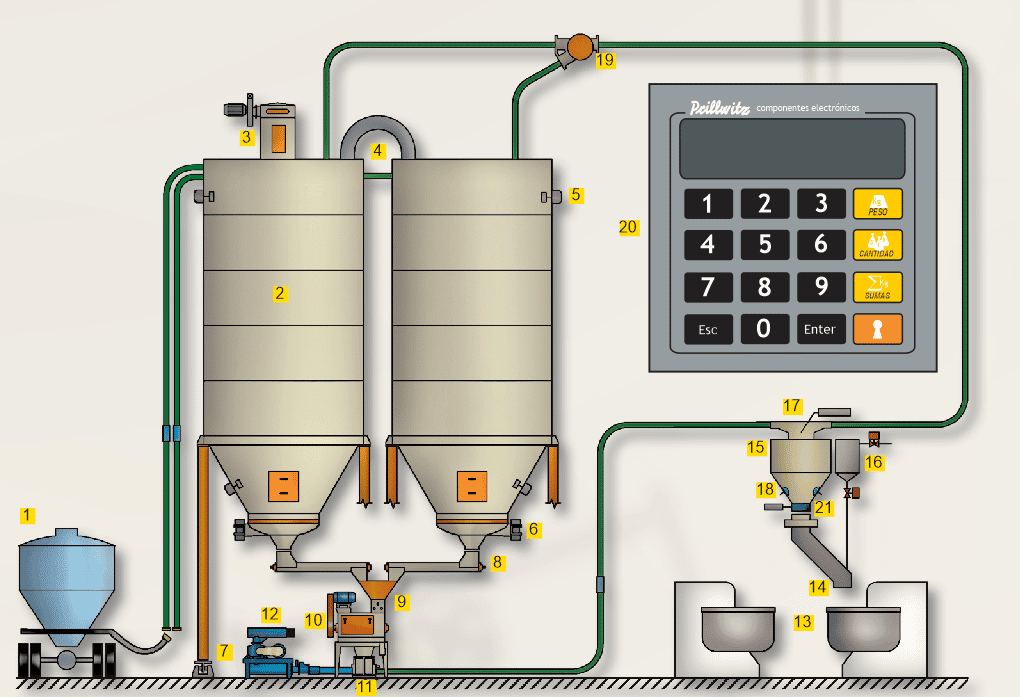

Typical diagram of a silo installation for storing bulk products, with pneumatic conveying to production stations.

01 Bulk Truck

02 Silos

03 HDF Filter

04 Suction

05 Level control

06 HAM Extractor

07 Scale

08 Conveyor thread HSF

09 Magnetic separator

10 Conical sifter

11 Airlock HSP

12 Compressor ASR

13 Kneading machines

14 Rotating tube

15 Weigh hopper

16 Water tank

17 Diverter valve

18 Fluidizer

19 Diverter valve

20 Display

01 Bulk Truck

02 Silos

03 HDF Filter

04 Suction

05 Level control

06 HAM Extractor

07 Scale

08 Conveyor thread HSF

09 Magnetic separator

10 Conical sifter

11 Airlock HSP

12 Compressor ASR

13 Kneading machines

14 Rotating tube

15 Weigh hopper

16 Water tank

17 Diverter valve

18 Fluidizer

19 Diverter valve

20 Display

Some of the raw materials we can handle:

- Wheat

- Maize

- Oats

- Coffee

- Cocoa

- Rye

- Beat

- Rice

- Girassol

- Chickpeas

- Soybeans

- Peanuts

- Peanuts

- Spices

- Balanced feed

- Pellets or feeds

- Crystalline sugar

- Impalpable sugar

- Cocoa

- Coffee

- Coriander

- Curcuma

- Gelatin

- Bone meal

- Fish flour

- Milk powder

- Dried beans

- Bread crumbs

- Batter

- Aluminum powder

- Atrazine

- Bentonite

- Borax powder

- Lime

- Caolin

- Activated carbon

- Calcium carbonate

- Cement

- Shell

- Quartz

- Titanium Dioxide

- Dolomite

- Fertilizers

- Monoammonium Phosphate

- Diammonium Phosphate

- Tricalcium Phosphate

- Mica

- Refractory Materials

- Sodium naphthalenesulfonate

- Pigments

- Soaps

- Salt

- Precipitated silica

- Caustic soda

- Magnesium sulfate

- Zinc sulfate

- Tanine

- Diatomaceous Earth

- Dyes

- Gypsum

- Lithium

- Afrecho and afrechillo

- Wheat semolina and semolina

- Semolina

- Rebasillo

- Zootechnical flour

- Maize semolina

- Semolina

- Polenta

- Wheat flour, corn flour, soy flour, etc.

- Germ

- Starch

- Hull

- Polycarbonate

- Vinyl polyvinyl chloride or PVC

- Polystyrene or PET

- Polyethylene

- Polypropylene

- Expanded polystyrene (Styrofoam)

- Sawdust

- Wood

- Cork

- Soap poder

- Pigments