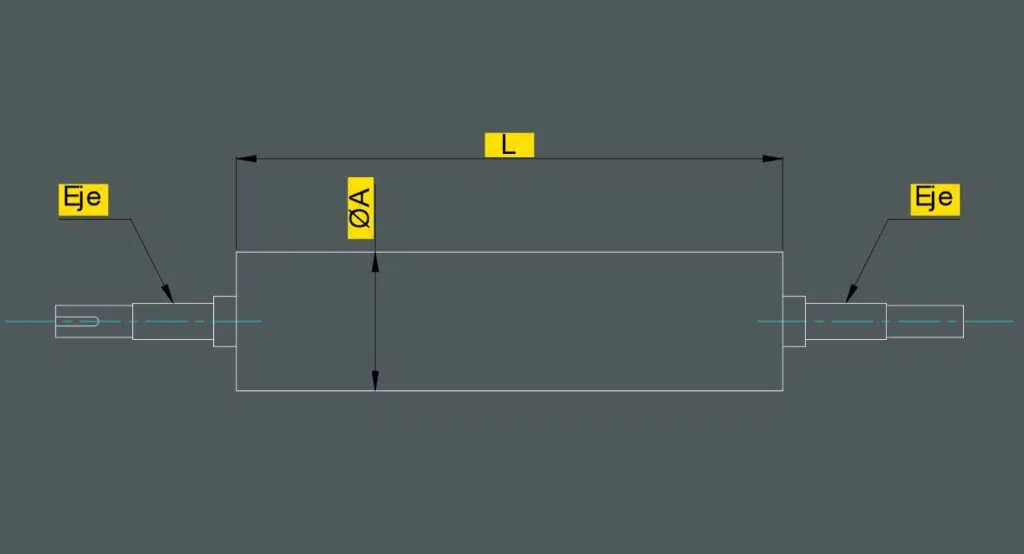

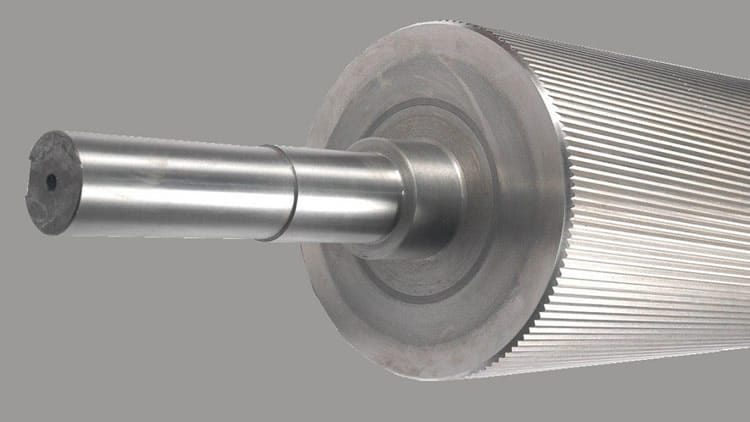

Manufactured under the strictest quality standards, Prillwitz rolls have excellent performance and long service life. They are built in centrifugal casting with specially selected and dynamically balanced steels. Therefore, we can assure you that these are rolls of unsurpassed quality.

Prillwitz rolls have been used for the crushing, grinding and rolling of various types of products all over the world for more than 100 years.

These can be smooth matted, grooved to order or ready for further machining. After many years of research and development, we have been able to prove that the innovative self-machining rolls considerably increase the performance of a flour mill.

With a wide range of models, Prillwitz supplies parts for the milling industry as well as for the food, chemical and mining industries.

SM Milling Rolls Test

The new rolls were tested in a 180 Tons/24h soft wheat mill.

The tests were carried out in passages C2 – C3 and C5 as there were complete benches for each passage. Standard rolls (hardness 430 – 470 HB) were installed on one side and two SM self-matting rolls were installed on the other side.

During the tests, the basic parameters were analyzed in the wheat mill along with the products obtained, over a period of more than three weeks.

RESULTS:

1. Intensification of the milling process

During the same period on both sides the SM self-milling rolls, produced slightly more flour.

Taking B1 value as 100%, the increase obtained was C2=2.1%, C3=1.8% and C5=1.3% with the self-matting rolls . Compared to normal rolls, 14%, 18% and 23% more flour was obtained, respectively. Considering the slightly coarser fraction of 200 the increase was higher (30%, 34% and 37% respectively).

This clearly shows that the milling process has been intensified.

Based on these good results, it was decided to replace all the smooth cylinders with SM self-matting smooth cylinders. After that, the capacity and extraction levels were monitored for a period of two years.

The quality of the grain being processed during the entire period was very uniform. The milling process, the equipment installed and the market situation were also similar during both periods.

The introduction of SM self-matting rolls was the only major change made. The results obtained during this study showed that flour extraction was 2.42% higher than in 1997 and mill capacity increased from 180 t/24hs to 200 t/24hs.

We therefore conclude that by placing SM coils in existing mills, capacity and performance can be increased. It is also possible to make a shorter diagram and take better advantage of the roller mills.

2. Improved flour quality

The flour produced improved. The results were as follows:

- The level of sedimentation (gluten quality) increased by 3-5 points.

- The water absorption in the flour increased by 3-5 points.

- The water absorption in the flour increased by 0.8-1.4%.

- The water absorption in the flour increased by 0.8-1.4%.

- The activity of alpha-amylase did not change.

- Experiments conducted in Canada showed that the protein level increased by approximately 0.25% and the flour cake was noticeably less spotted (ash) and brighter in color.

- In the trials, despite the 10% increase in mill capacity, the change in ash content was virtually non-existent. The tests showed that with a constant mill capacity, the ash content dropped by 0.16%.

3. Lower electrical power consumption

The power consumption of SM self-matting rolls, in the different roll banks, compared to normal rolls, was lower by 2.5% – 5.7%.

Overall, this showed that the smaller the particle size of the ground product, the greater the energy savings in grinding.

4. Lower the grinding temperature

One of the characteristics of soft rolls, working on compression passages, is the relatively high working temperature of the rolls.

With the SM self-matting cylinders, the working temperature was lower by 3.6-5.7 °C (6-10 °F).

Which in turn lowered the product temperature by 2.5-3.4 °C (2.5-3.4 °F).

5. Lower maintenance cost

During the two years, the SM self-matting cylinders installed have required no maintenance, retaining a sandblast finish. The results obtained show no noticeable deterioration.

During this years, more than 1000 Prillwitz SM self-matting rolls of various lengths and diameters have been installed in wheat mills.

As of the date of this technical report, the information received from all the mills where they confirms the benefits of the SM self-matting rolls in the grinding process and their superiority over other mills in the world.