Usable as a control sieve for both powdered and granulated products, this machine ensures the absence of foreign particles to re-enter the production line.

Its capacity depends on the product to be sifted and the granulometry that it intends to separate.

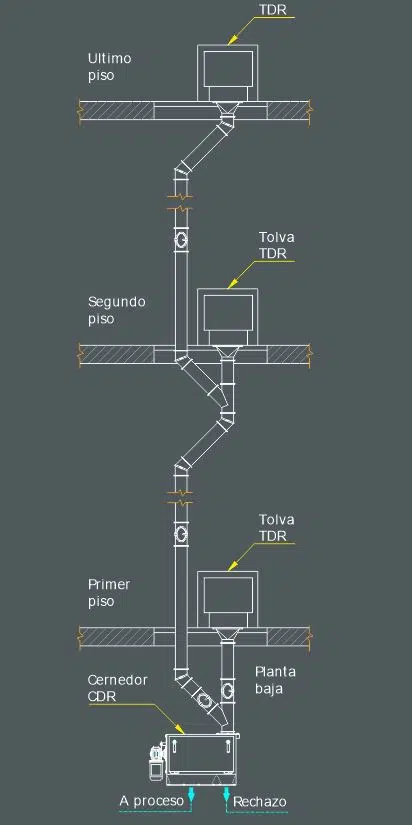

In flour mills it is used to re-enter the process, products that have left it due to clogging. To do this, it is combined with feed hoppers on each floor of the building.

Construction details of reprocessing dosing sifter

- The machine has an auger in its inlet that can be designed for the required capacity and can even be adjusted by placing an inverter for the drive motor.

- The sieve is made up of a perforated plate that also rotates, thus discarding all foreign particles.

- Due to its simple design devoid of complex parts, the CDR reprocessing dosing sifter is very low and easy to maintain.

- The equipment is normally supplied without feet, to be mounted directly on a silo or tank, however it can also be built with feet, unloading hoppers and waste deposit.

- Its construction can be both in carbon steel and stainless steel.

We build sieving machinery for any use and application, individually or in sets with their corresponding control and automation. The CDR rework dosing sifter is one of our many machines in the sorting and sieving group.